CONTACT US

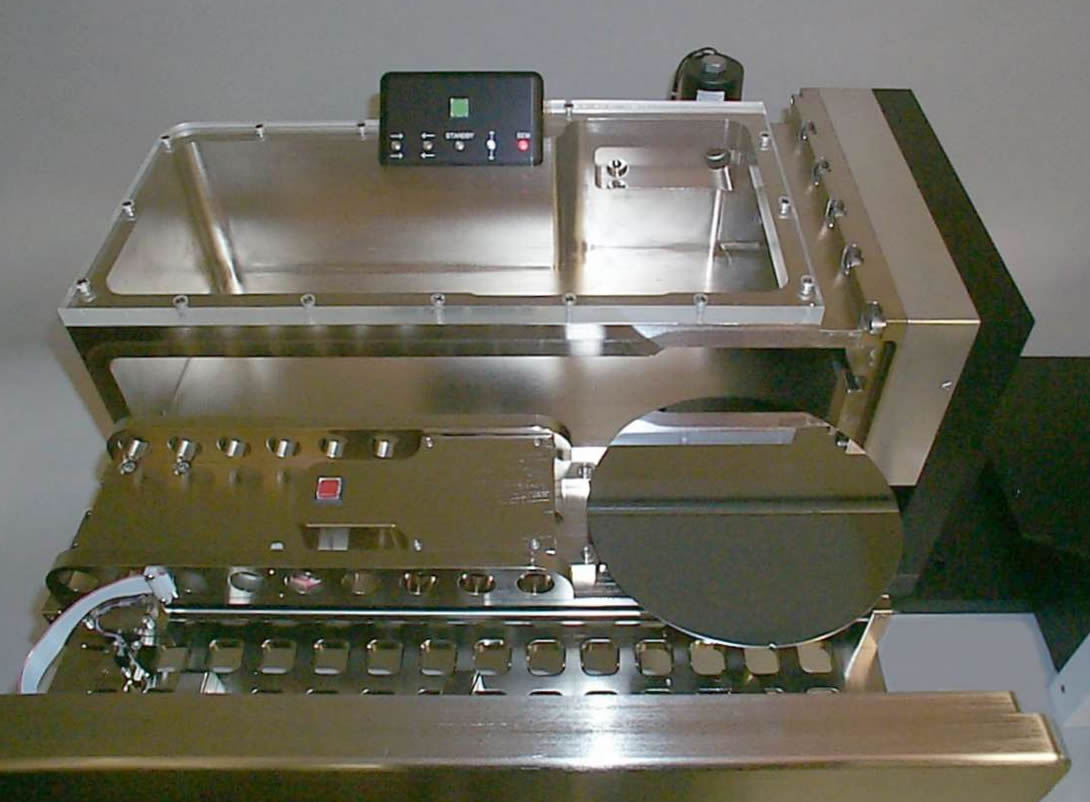

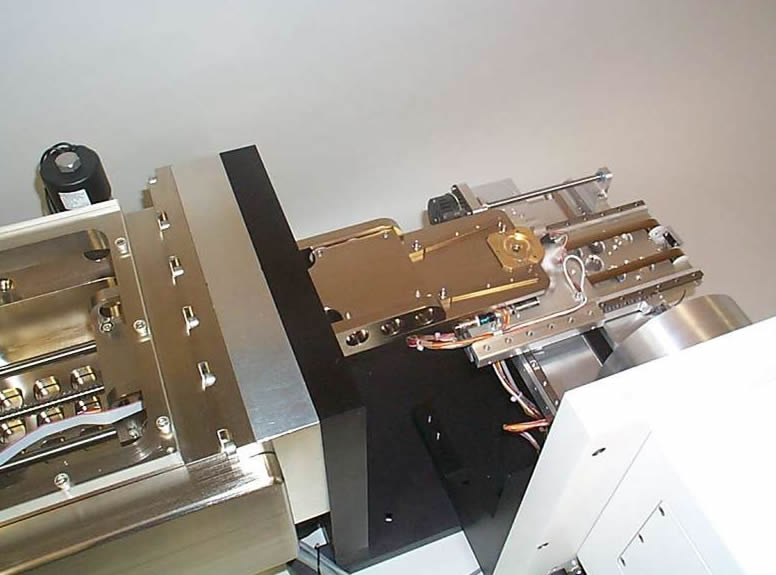

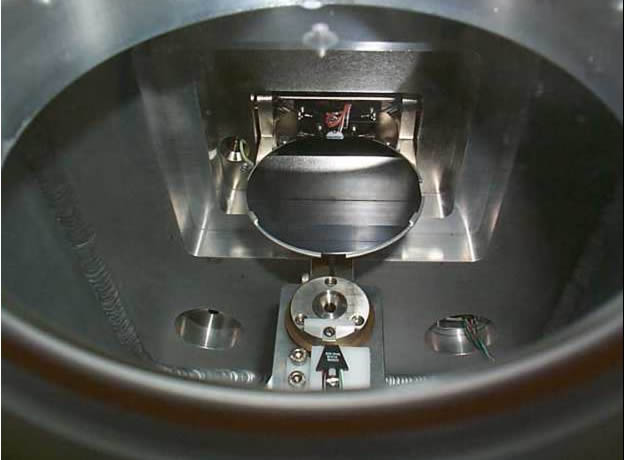

The Rapid Exchange System (RES) A-200 autoloader allow convenient, automatic sample exchanges while keeping the SEM or FIB host tool under vacuum. This greatly reduces pumping time, host tool contamination, and user interfacing. A simple, single-button interface is used to initiate sample exchanges, while five LEDs indicate the current autoloader status. A pincer switch, conveniently located internal to the autoloader, is used to manually actuate the carrier pincers when the user is exchanging samples on the transfer arm.

Key Features:

- Accepts sample sizes up to 200 mm in diameter.

- Interfaces to host tool via standard VAT® valve.

- Large top mounted viewing window and illumination source for excellent sample inspection while in vacuum.

- Multiple user interlocks to prevent usage during unsafe conditions.

- Vacuum interlocks to prevent operation unless under vacuum.

- Compatible with many SEMs.

- Highly accurate motorized lead screw inserting arm assures reliable repeatable sample loading.

- Windows™ based utilities software provided for system set up/diagnostics.

- Quick Fit dovetail design allows for fast sample exchanges.

- Reliable and simple design to reduce down time.

- Sample carrier sensors on host tool and autoloader transfer arm assures safe recovery in the event of site power failure.